Die Cutting Services

Cut & Mould Components specializes in the manufacturing of quality die-cut products. With modern machinery and quality materials, we are able to provide sustainable die cutting solutions in Malaysia.

Types of die-cutting services we specialize in.

Each type of die cutting service has its own unique advantages and applications. The choice of the appropriate method depends on factors such as the material being cut, the complexity of the design, the desired precision, and the volume of production.

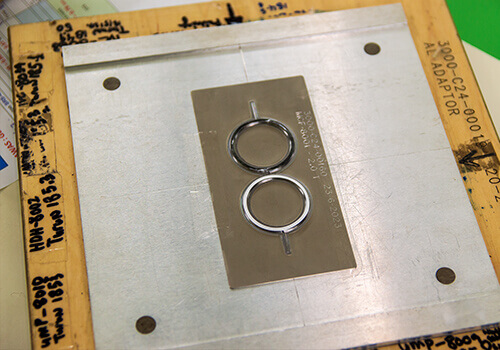

Custom Die Cutting

Custom die cutting involves the creation of unique, custom-designed dies to cut materials into specific shapes and sizes. It offers maximum flexibility and allows for the production of intricate and complex designs tailored to individual requirements.

Precision Cutting

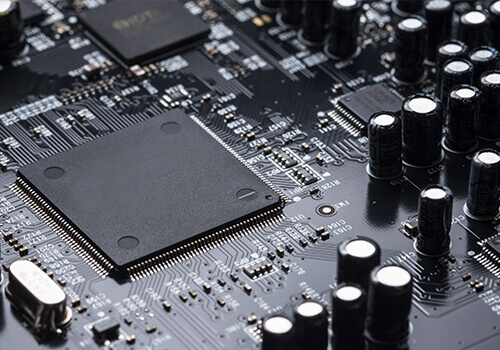

Precision cutting focuses on achieving extremely accurate and consistent cuts. It is commonly used in industries where precise tolerances are crucial, such as electronics, medical devices, and aerospace.

Kiss Cutting

Kiss cutting is a technique where the material is partially cut while leaving it attached to a backing sheet or liner. This allows for easy removal and application of the individual parts or labels. Kiss cutting is commonly used in applications such as adhesive labels, stickers, and decals.

Top rated die cut specialist

Any project size

No project is too small for us; we gladly accept die-cutting projects of any size, providing our expertise and dedication regardless of the project’s scale.

Quality assurance

We implement rigorous quality control processes to ensure that every die-cut product that leaves our facility meets the highest standards of excellence.

Cost effective

Our company’s optimization of material usage, efficient processes, and precision cutting techniques helps clients minimize waste and reduce production costs.

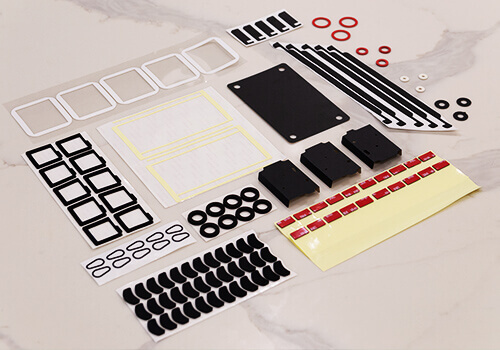

Common die-cut applications

Gasket – Automotive

Insulation – Electronics

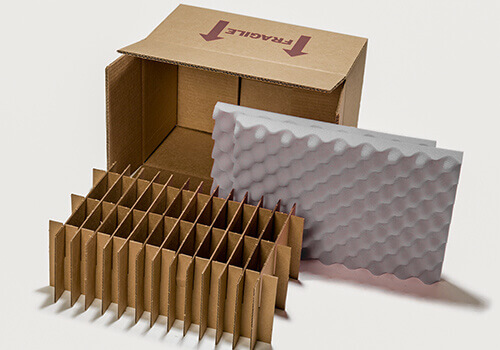

Cushioning – Packaging

Shock, Sound & Noise Absorbing – Studio

Air, Dust & Water Sealing – Electronics

Footing – Furniture

Adhesive Sheet – Automotive

Shielding – Camera

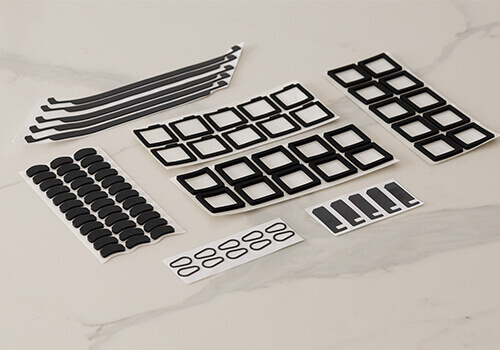

Common die cut products

Die cut foam

Die cut PU foam

Die cut PE foam

Die cut PVC

Die cut felt & fabric

Die cut rubber

Die cut gasket

Die cut adhesive tapes

Die cut silicone

Die cut insulation foil

Die cut heat shield

Die cut acoustic

Die cut sponge

Value added services

We work hard to understand our customers’ needs and provide them with premium services to fit their requirements. Moreover, we can optimize our die-cutting techniques to suit your production volume, resulting in increased efficiency and cost savings.

- Handwork

- Assembling

- Product packaging

- Gluing

High quality die cut materials we use

Lexan

Polycarbonate (PC)

Toray

Polyester film, PET film

3M

Medical tape, VHB tape

Nitto

Adhesive, Industrial tape, Silicone tape

Bridgestone

PU foam, foam

Inoac

Poron, PE foam, CR foam, EPDM foam

Die Cutting Solutions

Experience precision, versatility, and unmatched quality with our die cutting services. Contact us today to discuss your project requirements.